Call now

Vaillant Eco Tec R1 combi boiler repair Brixton, Vaillant F22, F75 error code.

posted on 03 Oct 2021Hi, I am Simon and I repair all models of Vaillant boilers. I am based in Upper Norwood & serve South London area. If your boiler suffers from F.22 or F.75 errors, or any other Vaillant error codes, please get in touch with me here:

Vaillant Repairs Crystal Palace

Vaillant Eco Tec Pro R1 – manufactured in 2007. This hugely popular boiler has been suffering from the following problems:

• hot water not reliable – stops working occasionally

• heating not reliable – sometimes works, but not always

• boiler needs resetting to get it to work again

When I took the case off I noticed that:

• this early version of Vaillant Eco Tec still had rubber hoses on return

• pressure gauge was at zero, but the boiler was still working – I assumed that the pressure sensor must be blocked

• I removed pressure relief connection – it was wet – pressure relief valve was leaking

• I checked the expansion vessel – it was flat and full of water. I also notice that expansion vessel looked like it was recently replaced

• there was no thermostat or any controls connected to the boiler, meaning that heating was always on

This Vaillant boiler have had the heating always on for last 14 years and the way it was controlled was by turning all radiator valves off in the summer. This caused the boiler to constantly turn itself on and off when all the radiators were of – so-called cycling, the best way to flatten your expansion vessel, activate the pressure relief valve and eventually corrode the system and destroy the boiler in the process. How has this boiler survived all this time in this set up is beyond me.

The work that I have done is as follows:

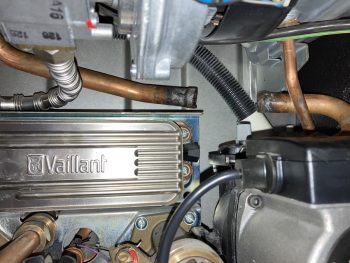

• replace the infamous rubber hose on the return pipework with a new rubber hose. I did not have the upgrade kit with that replaces hoses with copper connection with me and this was a short-term solution to some of this boiler problems. The problem with rubber hoses is the fact that they accumulate system dirt causing blockage to boiler components such as: main heat exchanger, pressure sensor, pressure gauge, etc. You can see the original rubber hose above the pump in the picture below.

I removed that hose, below you can see how much ‘crud’ it had accumulated.

New rubber hose got installed. I usually keep them as van stock, as there are still some of the early Vaillant Eco Tec R1 out there with those hoses. I do not think it makes sense to upgrade the boiler to copper connection at this stage, the boiler is 14 years old and if the hoses start creating problems again it will be new boiler time.

Below, you can see the return connection with hose removed and new hose installed.

With new hose installed, it was time to replace the blocked pressure sensor. Actually I was quite surprised that the boiler was working with a blocked sensor and flat expansion vessel, as this usually causes an F.75 error – no change of pressure detected at pump start. Since those pressure sensors are very unreliable and also a van stock and a relatively cheap components, I decided to replace it anyway.

Now the boiler finally was showing error F.22 – low pressure with no water and was not starting, as it was before – with no water in the system.

I have also pumped the expansion vessel to 0.8 bar as it was completely flat. No surprise here, any expansion vessel will go flat in no time if the boiler is constantly cycling forever.

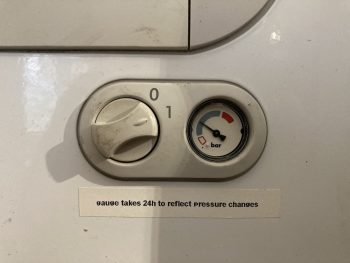

I tried to pressurize the system and quickly noticed that the pressure gauge was not moving. Another component was faulty! The pressure gauge was blocked. I managed to find a new pressure gauge in the van. This job was quickly depleting my Vaillant spare parts box in my Van!

The boiler got rained again. I quickly changed the pressure gauge and pressurized the boiler. Now we were getting somewhere. The boiler pressure gauge was showing correct pressure, pressure sensor was reading correct pressure, expansion vessel was topped up, flexible hoses, that caused those blockages were replaced. I also checked a ‘canoe filter’ and cleaned it when changing the pressure sensor. Canoe filter is a canoe shaped filter (hence the nick name) located before the flow goes into the plate heat exchanger, to protect the plate heat exchanger from blocking. I must say that I almost never see plate heat exchanger block on Vaillant Eco Tec boilers. It does the job, that little filter.

Below the boiler in question after all repairs.

After I installed the case back on, I noticed the little sticker by the pressure gauge. Instead of replacing the pressure gauge, someone just put a sticker that read: ‘ auge takes 24h to reflect pressure changes’. I can only assume a money pinching landlord put that sticker there instead of calling a plumber to repair the boiler. A gauge that does not show changes in pressure immediately may as well not be there. What a waste of time that sticker was and a great way to destroy your boiler, Sir or Madam! Do not do that again, please.

After managing to find all those spare parts in my van, there was one very important part I actually did not have, a thermostat. I booked another visit on this job to:

• supply and install new RF thermostat to save the boiler from constant cycling

• fully service the boiler – open up that combustion chamber and clean it, check combustion and adjust it if required

• Tee into flow and return and flush the boiler with my power flushing machine as there is still a slight blockage on main heat exchanger as boiler gets a bit too wide difference between flow and return on low rate – delta T gets a bit too wide and boiler cycles on hot water and heating, although it is not immediately obvious, as hot water temperature is retalively constant to the end user

That is a lot of work required to save a 14 years old boiler, and I am actually amazed it is still going, as this poor Vaillant Eco Tec Pro R1 has had a hard life of constant overheating and cycling.